4

5

SPECIFIC SAFETY RULES

• When battery pack is not in use, keep it away

from other metal objects like paper clips,

coins, keys, nails, screws, or other small metal

objects that can make a connection from one

terminal to another. Shorting the battery termi-

nals together may cause burns or a fi re.

• Under abusive conditions, liquid may be eject-

ed from the battery; avoid contact. If contact

accidentally occurs, fl ush with water. If liquid

contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause irritation

or burns.

SERVICE

• Have your power tool serviced by a qualifi ed

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

SYMBOLOGY

Volts

Direct Current

Impacts per Minute Under

Load (IPM)

No Load Revolutions per

Minute (RPM)

Underwriters Laboratories, Inc.

United States and Canada

• Hold power tool by insulated gripping surfaces,

when performing an operation where the fas-

tener may contact hidden wiring. Fasteners

contacting a “live” wire may make exposed metal

parts of the power tool “live” and could give the

operator an electric shock.

• Wear ear protectors when impact drilling.

Exposure to noise can cause hearing loss.

• Use only sockets and other accessories spe-

cifi cally designed for use on impact wrenches

and drivers. Other sockets and accessories might

shatter or break causing injury.

• Maintain labels and nameplates. These carry

important information. If unreadable or missing,

contact a MILWAUKEE service facility for a free

replacement.

• WARNING: Some dust created by power sanding,

sawing, grinding, drilling, and other construction

activities contains chemicals known to cause

cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as those dust masks that are spe-

cially designed to fi lter out microscopic particles.

Cat. No.

Volts

DC

RPM IPM

Mode Speed Mode Impacts

2452-20

2453-20

2454-20

12

12

12

1

2

1

2

1

2

0 - 1200

0 - 2650

0 - 1200

0 - 2650

0 - 1200

0 - 2650

1

2

1

2

1

2

0 - 3000

0 - 4000

0 - 2700

0 - 3550

0 - 2650

0 - 3500

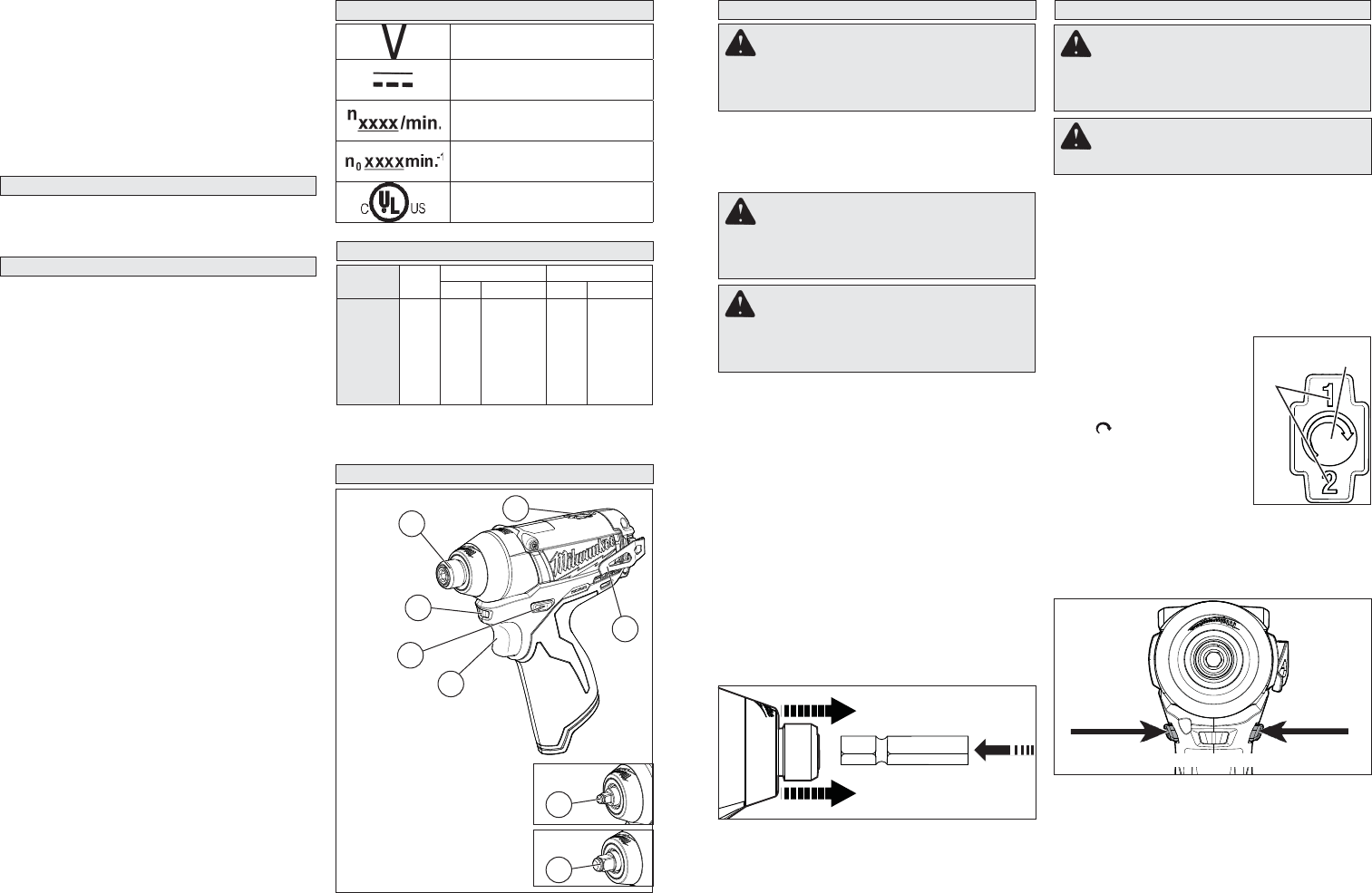

FUNCTIONAL DESCRIPTION

SPECIFICATIONS

1. Hex drive chuck

(2453-20)

2. LED

3. Control switch

4. Trigger

5. Belt clip

6. 2-Mode drive control

7. 1/4” Square drive shank

(2452-20)

8. 3/8” Square drive shank

(2454-20)

1

2

4

3

5

7

8

Fuel Gauge

To determine the amount of charge left in the bat-

tery, pull the trigger. The Fuel Gauge will light up

for 2-3 seconds.

To signal the end of charge, 1 light on the fuel

gauge will fl ash for 2-3 seconds.

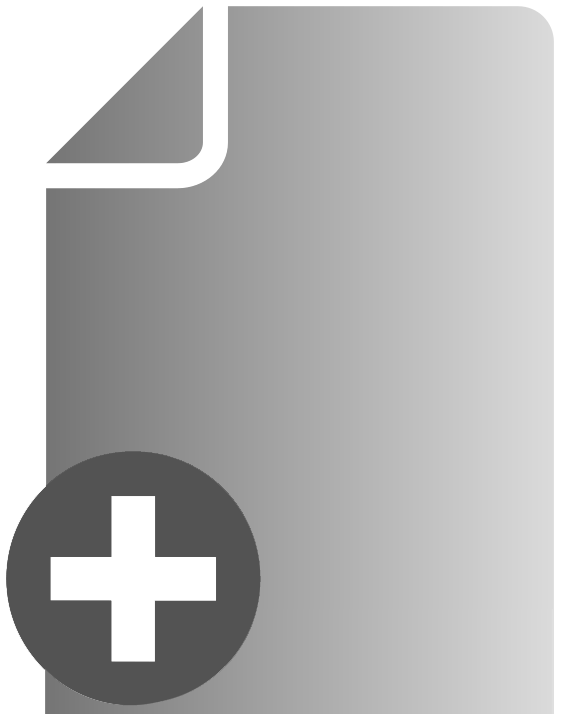

Using the Drive Control

The drive control button is used to adjust the torque,

rotation speed (RPM), and impact speed (IPM) for

the application (see Specifi cations chart for RPM

and IPM).

To select the drive control mode:

1. Pull and release the trigger to

turn on the tool. The current

mode indicator is lit.

2. Press the drive control but-

ton to cycle through the

2 modes. When the desired

mode indiator is lit, begin

work.

Using the Control Switch

The control switch may be set to three positions:

forward, reverse and lock. Due to a lockout mecha-

nism, the control switch can only be adjusted when

the ON/OFF switch is not pressed. Always allow

the motor to come to a complete stop before using

the control switch.

Push for

Forward

Push for

Reverse

PUSH TO CENTER TO LOCK

OPERATION

WARNING Always remove battery

pack before changing or removing

accessories. Only use accessories specifi -

cally recommended for this tool. Others may

be hazardous.

WARNING To reduce the risk of injury,

wear safety goggles or glasses with

side shields.

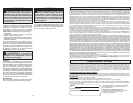

Attaching and Removing Accessories

Square drive shank (Cat. No. 2452-20, 2454-20)

These impact wrenchs are intended only for use

with sockets designed for impact wrenches that

have a 1/4" (Cat. No. 2452-20) or 3/8" (Cat. No.

2454-20) square drive. Other sockets could shatter

or break, causing injury.

1. To attach a socket or other accessory, align the

accessory with the drive shank and push it fi rmly

over the retaining ring.

2. To remove the accessory, pull the accessory off

the drive shank.

Hex drive chuck (Cat. No. 2453-20)

This driver is intended for use with drill and driver

bits with a 1/4" hex shank and ball detent recess.

1. To attach an accessory, press the shank into the

hex drive chuck.

2. To remove the accessory, pull out the ring and

remove the accessory. Release the ring.

ASSEMBLY

WARNING Recharge only with the

charger specified for the battery.

For specifi c charging instructions, read the

operator’s manual supplied with your charger

and battery.

Inserting/Removing the Battery

To remove the battery, push in the release buttons

and pull the battery pack away from the tool.

To insert the battery, slide the pack into the body of

the tool. Make sure it latches securely into place.

WARNING Use only sockets and other

accessories specifically designed

for use on impact wrenches and drivers.

Other sockets and accessories might shatter

or break causing injury.

WARNING Always remove battery

pack before changing or removing

accessories. Only use accessories specifi -

cally recommended for this tool. Others may

be hazardous.

6

Mode

Indicator

Drive Control

Button

1. For forward (clockwise) rotation, push the

control switch in the direction shown. Check the

direction of rotation before use.

2. For reverse (counterclockwise) rotation, push

the control switch in the direction shown. Check

the direction of rotation before use.

3. To lock the trigger, push the control switch to the

center position. The trigger will not work when

the control switch is in the locked position.

Always remove the battery pack before perform-

ing maintenance, changing accessories, storing

the tool and any time the tool is not in use.